Waste incineration

Waste incineration with recovery of recyclable materials using AIK processes and technologies.

AIK process for waste incineration plants – environmentally friendly heavy metal and wastewater solutions

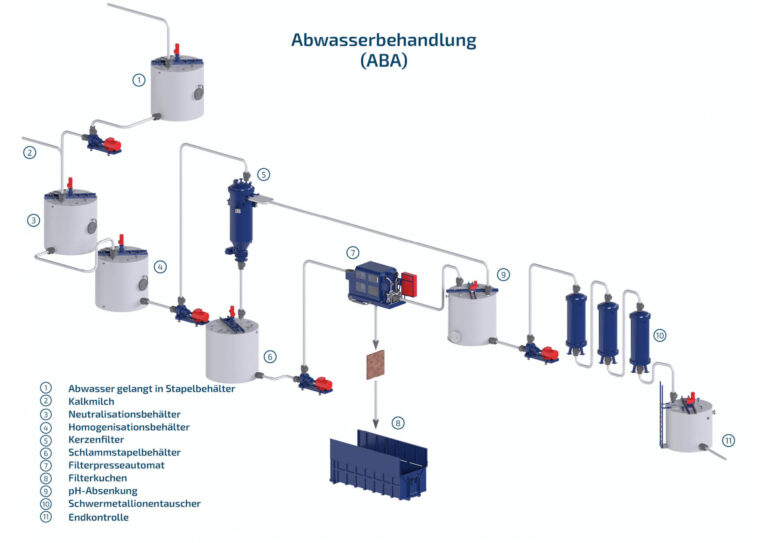

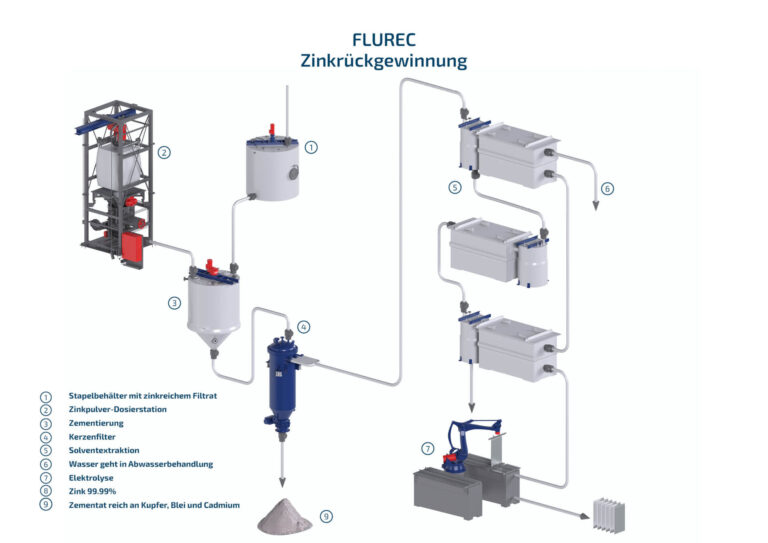

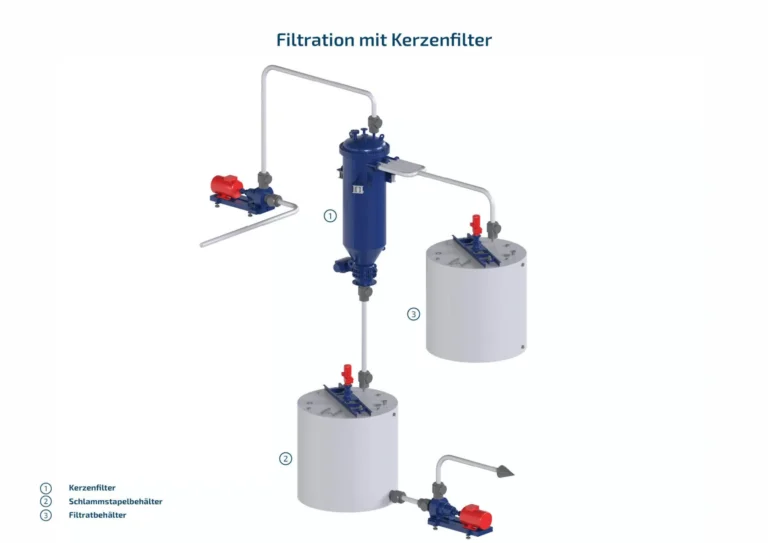

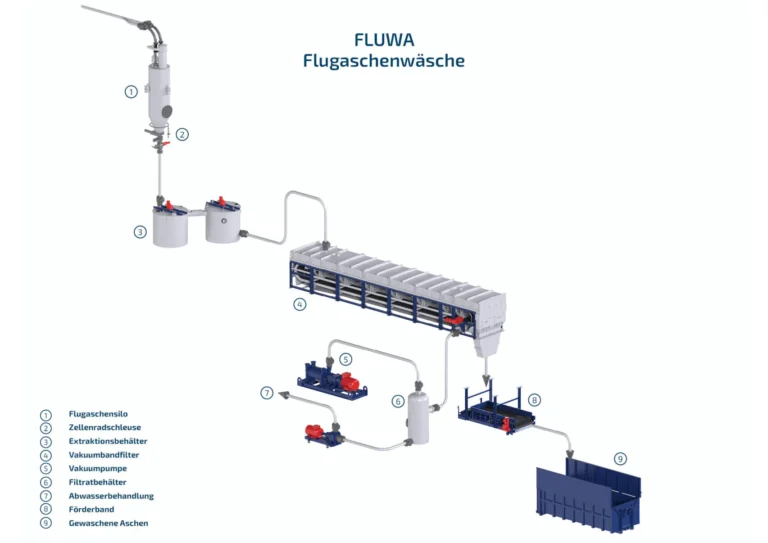

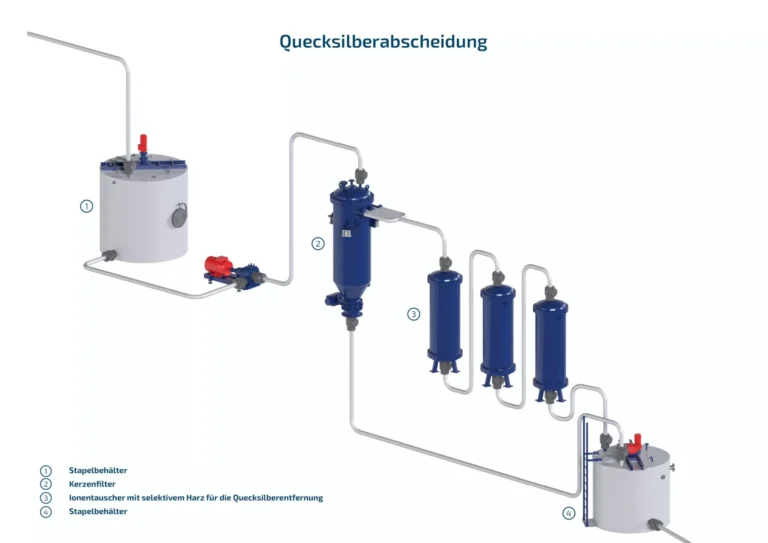

Our expertise extends across a wide range of services in the area of waste incineration plants. From fly ash washing (FLUWA) to the elimination of pollutants from wastewater to filtration with candle filters, mercury removal, zinc recovery and other heavy metal separations - all of these processes are the core of our service offering. We are also able to recover phosphorus from sewage sludge ash.

Our main focus is on obtaining valuable raw materials from waste materials. We invest annually in new technology developments and the continuous improvement of our existing systems, components and processes. Our goal is to leverage both innovative and proven practices to promote sustainability and make operations more efficient. We are actively committed to conserving materials and energy.

Our systems embody sustainability and contribute to value creation in the areas of business, energy and environmental protection. For this reason, we are a sought-after partner, consultant and plant manufacturer for authorities, special purpose associations and various sectors of the private sector when it comes to closing material cycles and implementing residue and wastewater treatment plants.

AIK Technik AG currently manages 26 of the 30 waste incineration plants in Switzerland as well as numerous others abroad. Find out more about our projects in our references.

Downloads

AIK process for waste incineration

Regarding waste incineration plants, there is the following relationship:

- Household garbage

- sweepings

- Recycling

- disposal

- fabric recycling

- collection points

- Circular Economy

- Recycling

- Material extraction household waste

- Urban Mining

- Recycling of phosphorus from sewage sludge incineration

- fly ash

- flue gas cleaning

In addition to the primary energy in the form of "heat / warmth", which is converted into electrical energy, steam and district heating, other "currents" are also generated. One of them is fly ash, also known as filter ash. The fly ash consists of particles that fly up with the combustion air and accumulate in the various stages of flue gas treatment. This part is about 2% of the amount of waste incinerated. In Switzerland, the fly ash is acid washed with the technology of AIK Technik AG for the purpose of recovering the heavy metals, especially zinc - see also filter and fly ash washing (FLUWA). The so-called FLUREC process is also available for this.

The washed ash is then landfilled. The so-called FLUREC process with the recovery of pure SHG zinc is also available for this. Another stream consists of the chemical liquid additives, which absorb undesirable substances during the cleaning of the flue gases and must be treated accordingly. These are cleaned in the wastewater treatment (ABA) with the technology of AIK Technik AG and can then be fed into an ARA or returned to the environment.

Incineration also produces slag (approx. 20% of the incoming waste), which is drawn off at the grate and contains solid rock-like material as well as ferrous and non-ferrous metals. The slag is processed, separating and collecting scrap iron as well as elemental aluminum, copper and brass. After that, when all recyclable materials have been removed, it is landfilled.

Memberships

Let us advise you free of charge.

In a free personal discussion with our experts, find out how the environmental impact of residue treatment can be reduced thanks to special processes and technologies.