Mercury separation

The Mercury Ion process consists of pre-filtration

and mercury ion exchange columns.

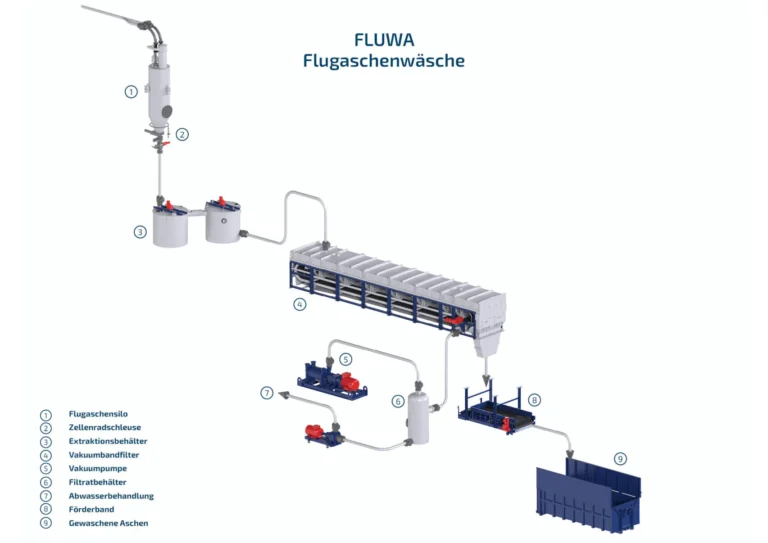

Filtering of blowdown water, quench water and mercury separation

The process water to be treated (acidic laundry wastewater or quench water, neutral laundry wastewater) from flue gas cleaning contains mercury, which is removed from the system in the first process stage. The process is based on two phases: pre-filtration of the laundry wastewater, followed by mercury removal via selective ion exchange columns. The pre-filtration of the laundry wastewater significantly improves the mercury removal efficiency of the ion exchanger. Thus, high loading densities can be achieved with selective ion exchange resins. The size of the components used always depends on the amount of wastewater to be treated.

In the process, approx. 98% of the mercury introduced into the waste incineration is removed, thus falling well below the limit values in the wastewater – an environmentally sound process that can be widely used in various branches of industry.

In the process, approx. 98% of the mercury introduced into the waste incineration is removed, thus falling well below the limit values in the wastewater – an environmentally sound process that can be widely used in various branches of industry.

Downloads

Mercury separation two-phase process

To the references

RESINA - ion exchange resin

Whether you need a mercury or heavy metals removal solution, we have the right ion exchange resin for you. Our resins are of the highest quality and enable effective and reliable removal of mercury or heavy metals from water using ion exchangers.

You will find more information here.

Memberships

We maintain the exchange in our department. That is why we are proud members of several associations.

Let us advise you free of charge.

In a free personal discussion with our experts, find out how the environmental impact of residue treatment can be reduced thanks to special processes and technologies.